-

Maintenance Support Services

Mechanical Maintenance and Machining Expert Services

Our Services

Mechanical Maintenance and Machining Expert Services

Industrial Maintenance Services

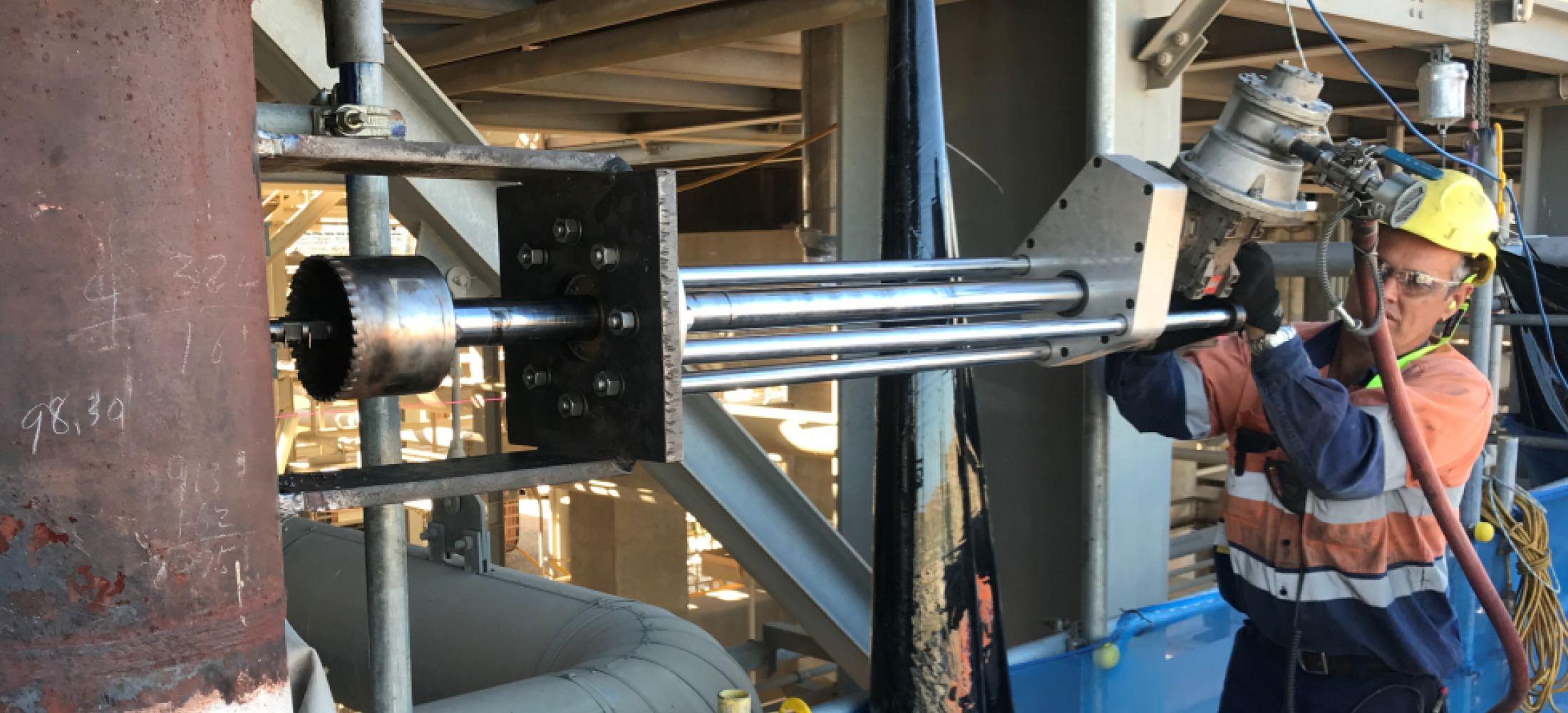

BLJ ‘s Mechanical Maintenance, On-site Machining and Site Shutdown Services are designed to keep your assets operational and efficient.

We bring our machining equipment to you and work in-situ, saving time and money. Whether it’s a day-to-day plant maintenance requirement, on-site milling, or specialist bundled services scope for a major shutdown, we have the experience, resources, and systems to assist.With our 18 years remote area multidiscipline experience, BLJ can provide high value solutions in a cost effective way across multiple market sectors.

All of BLJ In-situ Solutions services are supported by a robust Quality Management System and a Health, Safety and Environmental Management System. These systems ensure that the highest standard of service is continually achieved for clients and that environmental and safety legislative commitments relevant to the work environment and service provided are continually met.

With 18 years remote area multidiscipline experience, BLJ In-situ provides high value industrial maintenance solutions in a cost effective way, across industries and markets.

We understand your site requirements, possess strong technical knowledge, supported by a comprehensive, well maintained range of industrial equipment, we have the right machine for every job….from the one off – through to major ‘shutdowns’

Get in Touch with our Mechanical Maintenance & On-site Machining Experts

At BLJ, our expert technicians efficiently and effectively perform mechanical maintenance services both on-site and off-site. If you are looking to keep your mechanical assets operational and at optimal performance, contact the BLJ team today!

BLJ’s Mechanical Maintenance Services FAQ’s

As a result of our specialised services, BLJ In-situ Solutions has an excellent reputation as a Mechanical Maintenance and Shutdown Service Provider. To learn more about our range of services, take a look at our FAQs below.

Controlled bolting is the technique of applying an accurate torque load to a mechanical joint in order to assure joint integrity. Because bolted joints are frequently one of the most prevalent parts in industrial components, the durability of each connection is critical. At BLJ, we have specialised methods for accurately and precisely tightening or loosening bolts in various mechanical applications.

Controlled bolting is essential in industries where secure and reliable bolted connections are crucial. Properly tightened bolts provide better load transfer and stability, enhancing the overall performance of equipment or structures. This can improve productivity, reduce wear and tear, and increase equipment lifespan. By ensuring accurate and consistent bolted connections, controlled bolting helps prevent costly repairs, rework, or equipment damage caused by improper bolt tightening. It also minimizes the risk of unplanned downtime, saving businesses valuable time and money.

Flange Joint Management involves the systematic approach to ensuring the integrity and reliability of flanged connections in industrial piping systems. It includes activities such as inspection, maintenance, and optimization of flange joints to prevent leaks, improve safety, and enhance operational efficiency. Flanged joints are critical components in a piping system and are subject to wear and tear over time, so regular maintenance is crucial. At BLJ, we have specialised methods for accurately and precisely maintaining flange joints to minimise downtime.

Flange Joint Management offers several benefits including helping prevent leaks and associated safety hazards, reducing downtime and maintenance costs, extending the service life of flange joints, and enhancing overall system integrity. Proper management ensures compliance with industry standards and regulations, improves operational efficiency, and minimises the risk of environmental contamination.

Hot tapping is a method of making a connection to an existing pressurised system, such as a pipeline or pressure vessel, without the tank or pipe experiencing downtime. This prevents costly and potentially dangerous hazards while allowing for continued operation.

BLJ’s Hot Tapping services allow for the continued operation of the plant and individual systems while repairs or modifications are being made. This means shutdown time is eliminated, saving you time and money. Hot Tapping also serves as a safe and efficient way of making connections to pressurised systems.

Shutdown services are comprehensive maintenance and repair activities carried out on production-critical assets and infrastructure in various industries. These services involve halting all plant activities to facilitate repairs, maintenance and equipment replacements. Shutdowns are crucial for ensuring plant reliability, compliance with safety regulations, and optimising plant performance.

BLJ In-Situ Solutions personnel are able to complete servicing operations to plant equipment on-site with portable machines to increase plant up-time, safety and productivity while reducing the time, labour and transport costs of assembling and reassembling equipment.

Any issue in the plants equipment can put the project over-budget, especially if items need to be disassembled and transported to be machined offsite. Any project facing this problem needs a fast and reliable solution to get the operation back up and running as quickly as possible. Using BLJ In-Situ Solutions portable machining equipment, our technicians are able to conduct high-quality, precision machining in-situ. This allows significant savings on personnel’s time, plant servicing and traditional maintenance costs.

Our on-site machining solutions are ideal for any plant or construction project which needs quick and efficient in-situ machining services. Field maintenance is the best choice for planned or emergency shut-downs to mill, bore, drill, trepan or any maintenance task where adjustments to machinery are required.

Where traditionally equipment would need to be disassembled and machined off-site in a workshop, our portable machining equipment allows our expert team to conduct work in-situ.

Shutdown services facilitate the onsite maintenance and repair of plant equipment. This includes:

- Controlled Bolting: Controlled bolting is the technique of applying an accurate torque load to a mechanical joint in order to assure joint integrity. Because bolted joints are frequently one of the most prevalent parts in industrial components, the durability of each connection is critical. At BLJ, we have specialised methods for accurately and precisely tightening or loosening bolts in various mechanical applications.

- Flange Joint Management: Flange Joint Management involves the systematic approach to ensuring the integrity and reliability of flanged connections in industrial piping systems. It includes activities such as inspection, maintenance, and optimization of flange joints to prevent leaks, improve safety, and enhance operational efficiency. Flanged joints are critical components in a piping system and are subject to wear and tear over time, so regular maintenance is crucial. At BLJ, we have specialised methods for accurately and precisely maintaining flange joints to minimise downtime.

- Flange Facing: Flange Facing is the process of machining the contact surfaces of flanges to create smooth and flat mating surfaces. It involves removing imperfections, such as corrosion, roughness, or damage, from the flange faces to ensure a proper seal when the flanges are bolted together. BLJ technicians perform field flange-facing services using specialised machines and tools.

- Hot Tapping: Hot tapping is a method of making a connection to an existing pressurised system, such as a pipeline or pressure vessel, without the tank or pipe experiencing downtime. This prevents costly and potentially dangerous hazards while allowing for continued operation.

BLJ In-Situ Solutions personnel are able to complete servicing operations to plant equipment on-site with portable machines to increase plant up-time, safety and productivity while reducing the time, labour and transport costs of assembling and reassembling equipment.

Hiring a professional team to perform machining services is essential to ensure efficient machining execution and safety compliance during maintenance activities. The knowledgeable team at BLJ possess the expertise, experience, and resources to handle complex projects, optimise maintenance tasks, and minimise operational risks. Their proficiency ensures that tasks are performed precisely and adhere to industry standards, leading to successful outcomes and minimised downtime.

Our Recent Projects

"*" indicates required fields

admin@bljiss.com.au

admin@bljiss.com.au 07 3245 2203

07 3245 2203