-

Hot Tapping

Allowing work to continue while modifications are being made

Hot Tapping

Allowing work to continue while modifications are being made

Hot Tapping Solutions

BLJ In-situ Solutions has as a strong reputation a Mechanical Maintenance and Shutdown Service Provider due to our expert services, which include Hot Tapping services.

Hot tapping allows safe cutting into pressurised lines and vessels, flowing under reduced pressure and maintaining temperature. A hole is cut into a pipeline or vessel to allow for new pipeline tie-ins to be installed.

This means that a pipeline or vessel can continue to be in operation whilst modifications are being conducted. We stock Hot Tapping equipment for up to 16” diameter.

You can read about a recent hot tapping project our team have worked on where a 12″ Hot Tap was required on a stainless steel tank to serve as a drain point.

BLJ In-situ Solutions is certified and registered by TQCS International Pty Ltd to ISO 9001:2015 Quality Management Systems standard. All work undertaken by the BLJ team is executed in accordance with its Quality Management System processes.

Download Our Hot Tapping Enquiry Form

Please use the button below to download our Hot Tapping Enquiry Form or complete our online enquiry below.

Hot Tapping Services FAQ’s

As a result of our specialised Hot Tapping services, BLJ In-situ Solutions has an excellent reputation as a Mechanical Maintenance and Shutdown Service Provider. To learn more about our Hot Tapping services, take a look at our FAQs below.

Hot tapping is a method of making a connection to an existing pressurised system, such as a pipeline or pressure vessel, without the tank or pipe experiencing downtime. This prevents costly and potentially dangerous hazards while allowing for continued operation.

Hot tapping is frequently used in order to repair areas that have experienced mechanical damage or corrosion over time or to add branches for modifications to the system. It can also be used to install new equipment, such as valves or meters.

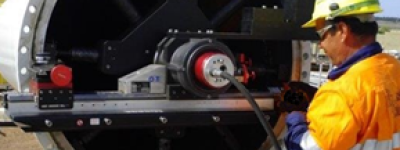

There are a number of different methods for hot tapping, but they all involve the use of specialized equipment and trained personnel. The most common method is to use a hot tapping machine, which drills or cuts a hole in the pipe and then inserts a fitting that allows for the connection of a new pipe or branch.

BLJ’s Hot Tapping services allow for the continued operation of the plant and individual systems while repairs or modifications are being made. This means shutdown time is eliminated, saving you time and money. Hot Tapping also serves as a safe and efficient way of making connections to pressurised systems.

There are many risks associated with Hot Tapping. If this procedure is performed incorrectly, it can cause damage to the system resulting in hazardous leaks or spills. This, in turn, can cause harm to those around the leak or spill. Any damage will call for expensive repairs and plant downtime while repairs are undertaken. To avoid these risks, hiring a qualified professional to complete high-quality Hot Tapping services is essential for project success.

Our Hot Tapping Projects

Hot Tapping Stainless Steel Tank

BLJ was engaged by a leading Queensland construction company to undertake a one-off 12” 150Lb Hot Tap on a stainless steel tank that will serve as a drain point – the tank was to be emptied for inspections.

Our technicians utilised a T37 Hot Tap Machine to perform the 12” 150 Lb Hot Tap into the 11,200-diameter stainless steel tank. The product in the tank was beer sludge with 12% ethanol.

The hot tapping process was completed without leakage or loss of fluid. The job was successfully completed in 1 x 8-hour day shift.

With 18 years remote area multidiscipline experience, BLJ In-situ provides high value solutions in a cost effective way, across industries and markets.

"*" indicates required fields

admin@bljiss.com.au

admin@bljiss.com.au 07 3245 2203

07 3245 2203